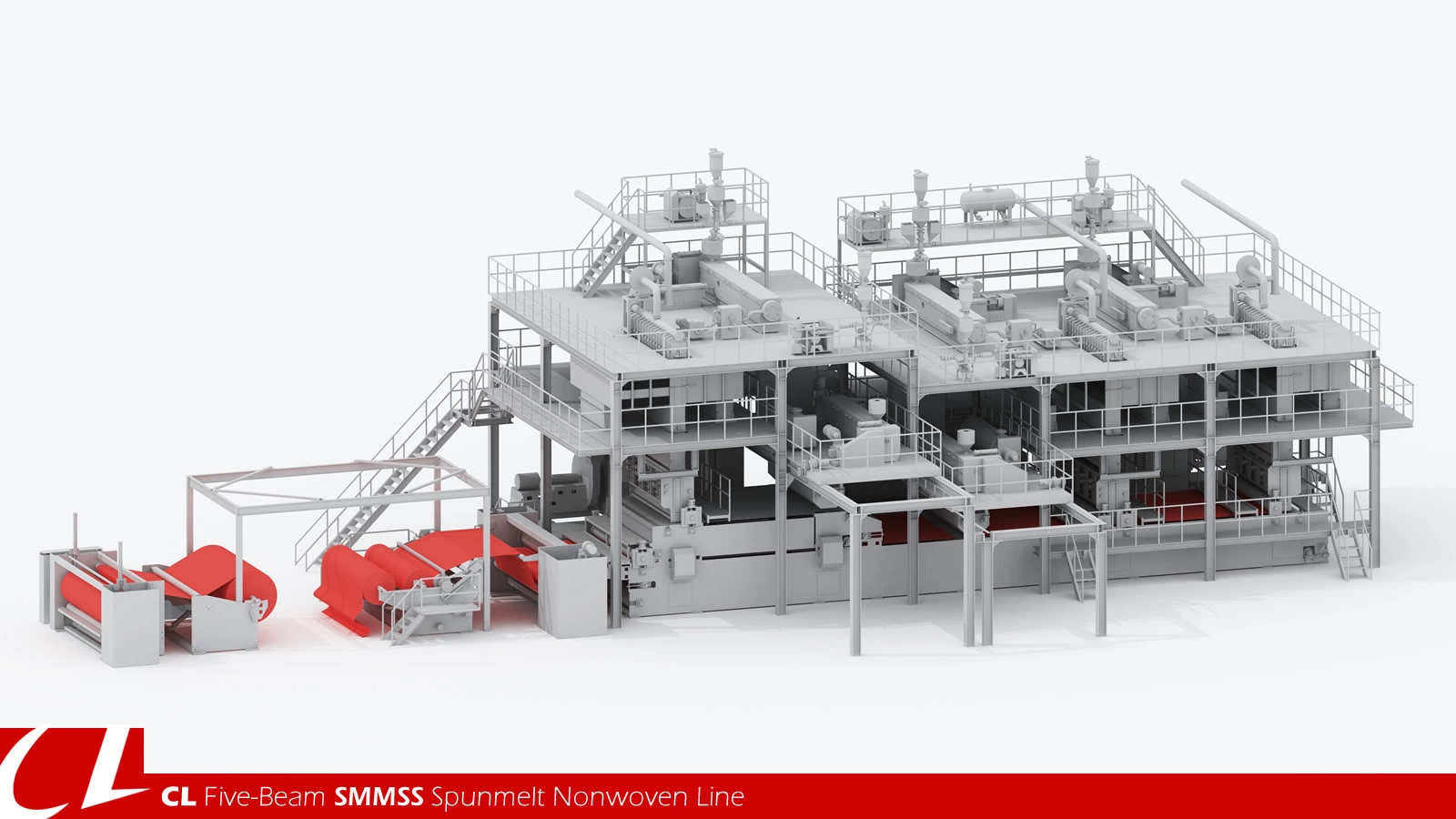

SMMSS Nonwoven Fabric Making Machine

In 2009, CL established China's first five-beam SMMSS line.

The SMMSS fabric is composed of three layers of spunbond nonwoven fabric and two layers of meltblown nonwoven fabric. This versatile material is used in manufacturing nonwoven products for medical applications, including surgical gowns, protective clothing, masks, and drapes. Moreover, it is highly suitable for hygiene products like top sheets, back sheets, core wraps, and leg cuffs for diapers and sanitary napkins.

Technical Specification

Part One: Production Line Request

- Product width:2400/3200/4200mm(effective width)

- Maximum roll diameter:2M

- Main raw material:Polypropylene chip

- Product GSM:8~80g/㎡

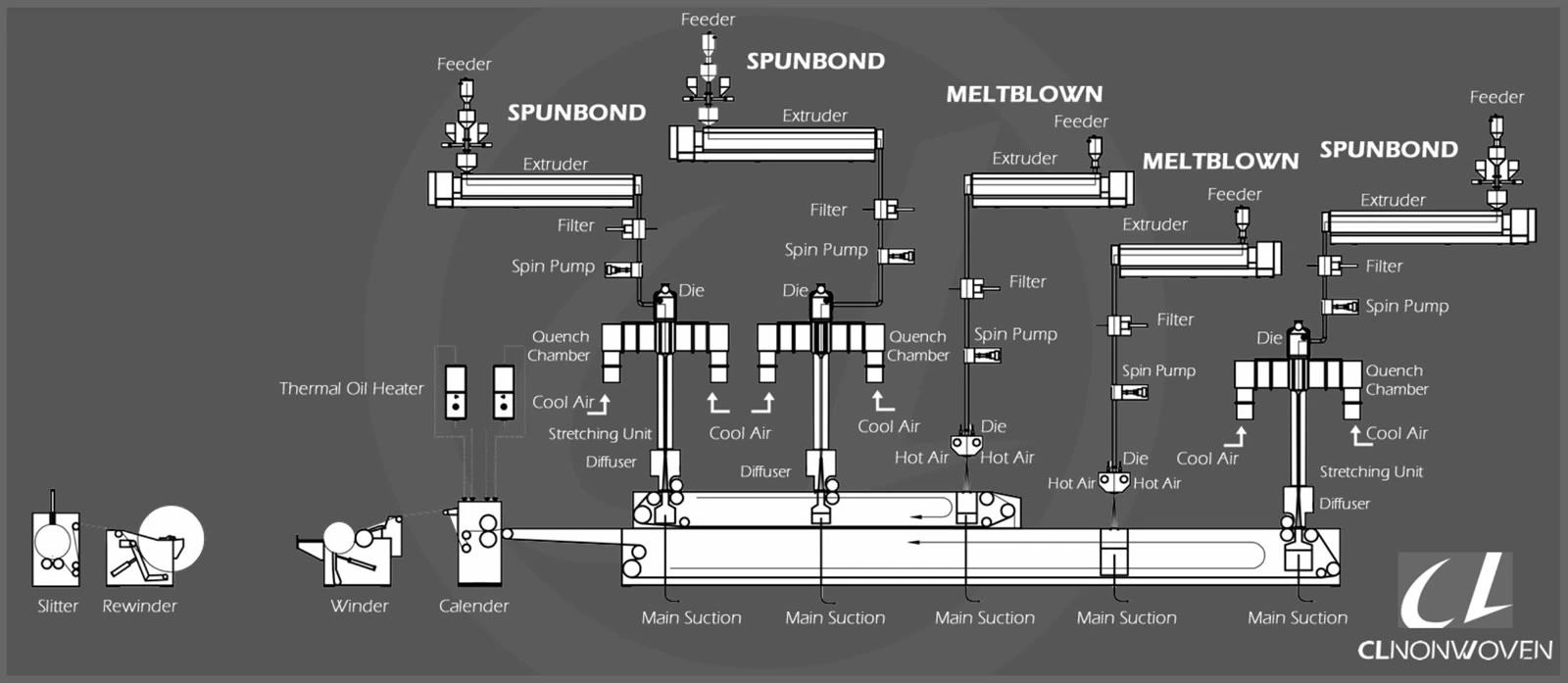

- Procedure diagram for spunbond:

Procedure diagram for meltblown:

PP chips tank A ->pneumatic conveying -> extruder melting -> filtering -> web forming

Part Two: Machine Standard Instructions (Spunbond Part)

- Feeding system: 3 sets

- Main extruder: 3 sets

- Recycle extruder: 3 sets

- Hydraulic net changing device: 3 sets

- Die: 3 sets

- Monomer: 3 sets

- Cooling, stretching device: 3 sets

- Web former: especially designed for catching fibers.

- Electrical control system, critical parts imported, relay, contactor and as such adopt high quality electrical brand company

- Steel structure: 1set

- Two rollers calender

- Winder: 1 set

- Full set high-speed off-line slitter Principle: off-line slitting, Positive drive, constant tension control, tension adjustable

Part Three: Machine Standard Instructions (Meltblown Part)

- Feeding system: 2 sets

- Main extruder: 2sets

- Hydraulic net changing device: 2 sets

- Die: 2 sets

- Web former: especially designed for catching fibers. Including: Electrical control system, critical parts imported, relay, contactor and as such adopt high quality electrical brand company

- Air heating system

- Air compressor

| Effective Width | GSM Range | Max. Speed | Annual Capacity | Daily Capacity |

|---|---|---|---|---|

| 2400MM Line | 8-80 | 700 m/min | 9000 Tons/Year | 25 Tons/Day |

| 3200MM Line | 8-80 | 700 m/min | 12000 Tons/Year | 33 Tons/Day |

| 4200MM Line | 8-80 | 700 m/min | 16000 Tons/Year | 45 Tons/Day |

SMMSS Nonwoven Fabric Making Machine Process Flow