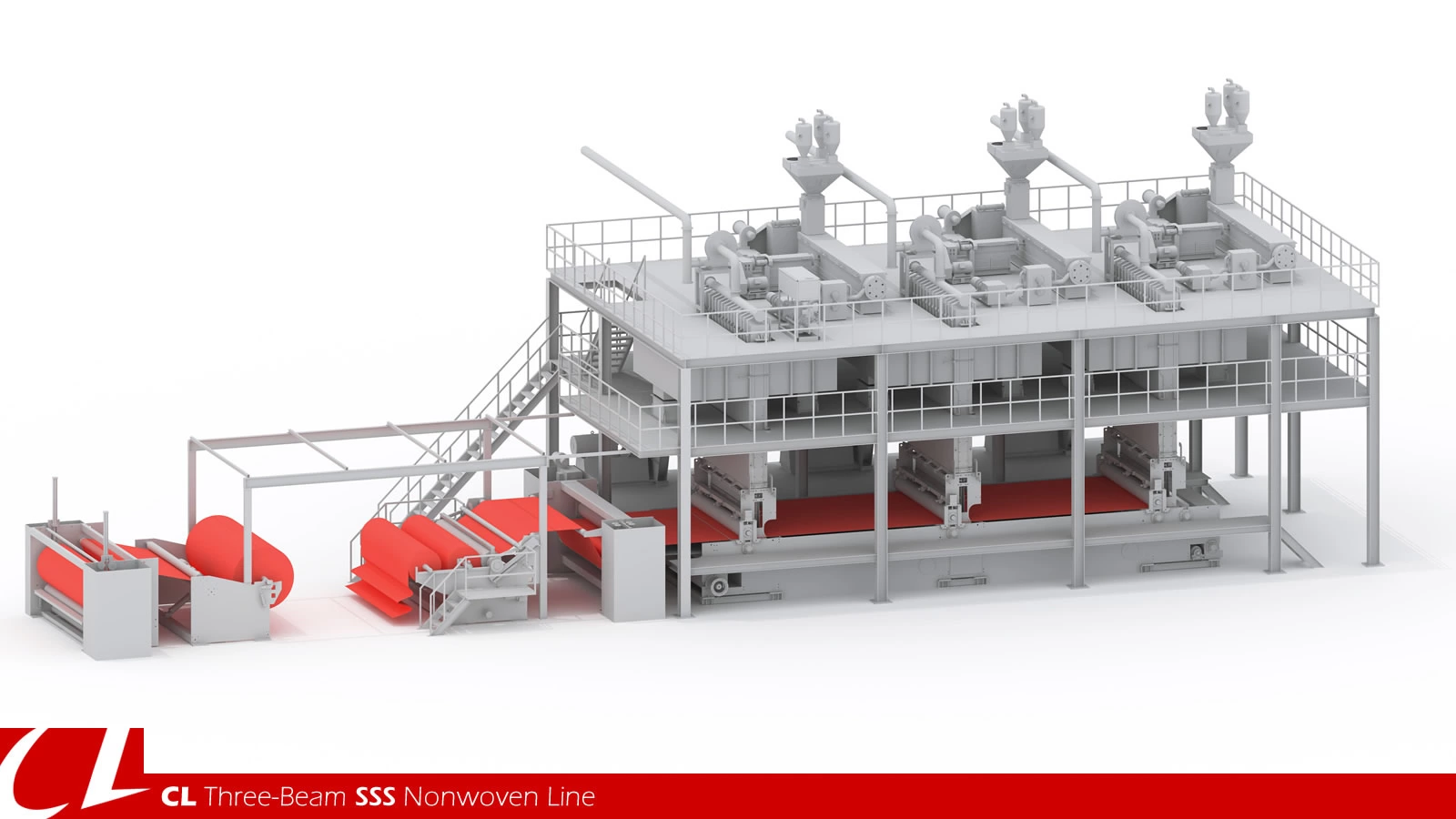

SSS Nonwoven Fabric Making Machine

SSS non-woven fabric can be specially treated to enhance its suitability for the hygiene sector.

Renowned for its superb evenness and outstanding softness, this material is extensively used in the top sheets and back sheets of most diapers and sanitary napkins on the market

Technical Specification

Part One: Production Line Request

- Product width:2400/3200/4200mm(effective width)

- Maximum roll diameter:2M

- Main raw material:Polypropylene chip

- Production line adopts the technology of slit negative pressure stretching.

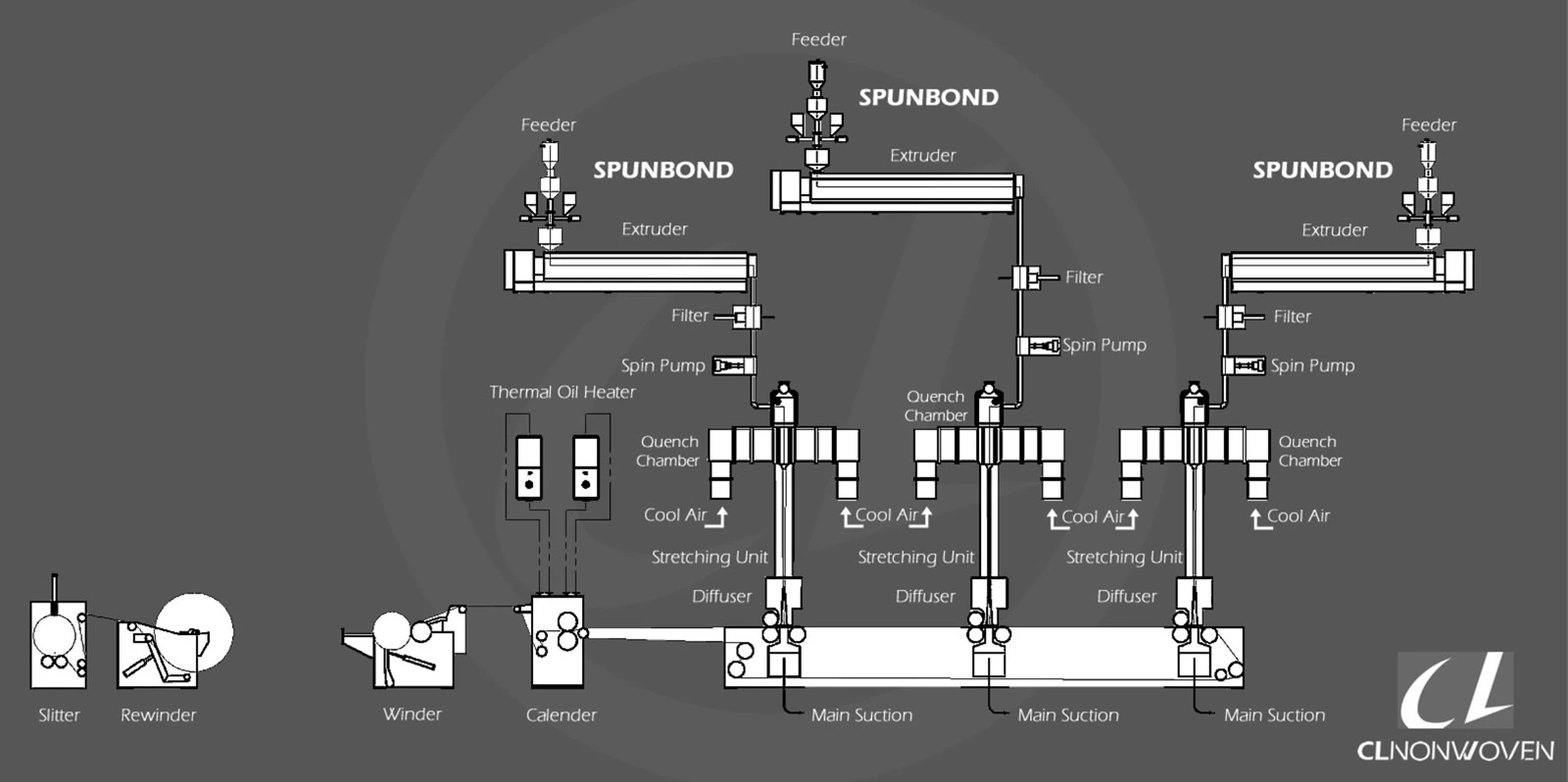

- Procedure:Procedure diagram for spunbond:

PP chips tank A -- pneumatic conveying -- extruder melting -- filtering -- spinning -- stretching -- web forming -- calendar bonding -- winding -- offline slitter

Part Two: Machine Standard Instructions

- Feeding system and dosing system: 3 sets

- Main extruder : 3 sets

- Recycle extruder

- Hydraulic screen change device : 3 sets

- Spinning Die Body: 3 sets

- Monomer: 3 sets

- Cooling, stretching device: 3 sets

- Web former: especially designed for catching fibers Electrical control system, critical parts imported, relay, contactor and as such adopt high quality electrical material which are made by high quality brand

- Steel structure: 1set

- Two rollers calender: 1set

- Winder: 1 set

- Full set high-speed off-line slitter

| Effective Width | GSM Range | Max. Speed | Annual Capacity | Daily Capacity |

|---|---|---|---|---|

| 2400MM Line | 8-100 | 600 m/min | 6800 Tons/Year | 19 Tons/Day |

| 3200MM Line | 8-100 | 600 m/min | 9000 Tons/Year | 25 Tons/Day |

| 4200MM Line | 8-100 | 600 m/min | 12000 Tons/Year | 33 Tons/Day |

SSS Nonwoven Fabric Making Machine Process Flow